Bessemer Steel Process: Revolutionizing The Way We Make Steel

Steel production has come a long way since the days of ancient blacksmiths pounding metal over hot coals. But nothing changed the game quite like the Bessemer Steel Process. This groundbreaking method, developed in the mid-19th century, transformed how we make steel, making it faster, cheaper, and more efficient than ever before. It’s like the iPhone of steel production – completely changing the industry overnight. And guess what? We’re about to dive deep into how it all went down.

Now, I know what you're thinking – "Why should I care about some old steel-making process?" But here's the thing: this process laid the foundation for the modern world as we know it. From skyscrapers to cars, the Bessemer Steel Process helped build the infrastructure that powers our daily lives. So, even if you're not a metallurgy nerd, stick around because this story is actually pretty fascinating.

And don’t worry, I won’t bore you with dry textbook jargon. We’re gonna break it down in a way that makes sense, with some fun facts and real-world examples thrown in for good measure. So, buckle up, because we’re about to take a trip back in time to see how a guy named Henry Bessemer changed the world with a little bit of air and a whole lot of ingenuity.

- Kokosnuss Rezepte Vorteile Mehr Entdecken Dein Guide

- Hintere Schulter Trainieren Die Besten Bungen Fr Dich

What Exactly is the Bessemer Steel Process?

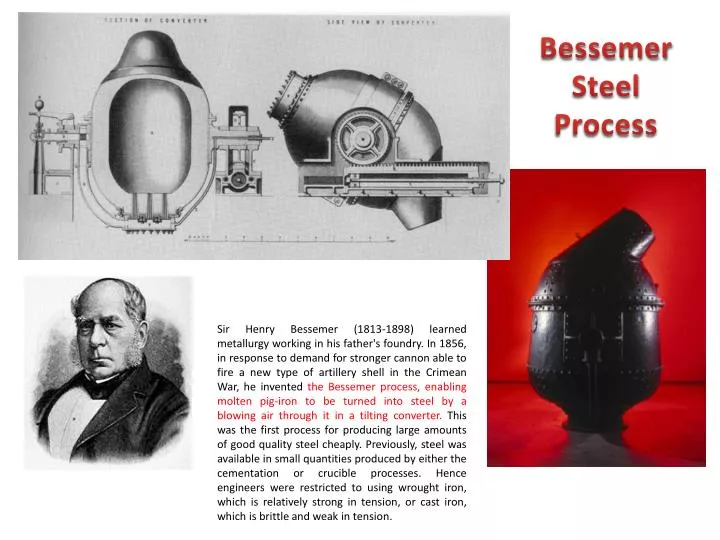

Alright, let’s start with the basics. The Bessemer Steel Process is basically a method of making steel by blowing air through molten iron to remove impurities. Yeah, it sounds simple enough, but back in the day, this was revolutionary stuff. Before Bessemer came along, making steel was a slow, expensive process that involved a lot of manual labor and guesswork.

But here’s the kicker: Henry Bessemer figured out that by blasting air through molten pig iron, you could burn off the carbon and other impurities, leaving behind pure steel. It’s kind of like using a leaf blower to clean your driveway – only instead of leaves, you’re getting rid of unwanted elements in the iron. Genius, right?

How Does it Work?

Let’s break it down step by step:

- Ltere Frauen Spa Entdecke Heie Milfs Mehr Neue Videos

- Das Kleine Bse Buch Lsungen Rtsel Entdecke Die Geheimnisse

- Melting the Iron: First, you take some pig iron – that’s the raw iron you get from smelting ore – and melt it in a big furnace. Think of it like heating up a pot of soup before you start adding ingredients.

- Blowing Air: Next, you blast air through the molten iron. This creates a chemical reaction that burns off the carbon and other impurities. It’s like using a flamethrower to get rid of weeds in your garden – quick and effective.

- Cooling Down: Once the impurities are gone, you let the steel cool down and solidify. Voila! You’ve got yourself some high-quality steel ready to be used for whatever you need.

Now, I know what you’re thinking – "Why not just skip the air-blasting part and go straight to the cooling?" Well, my friend, that’s where the magic happens. The air blowing is what makes the Bessemer Process so efficient. Without it, you’d still be stuck with all those pesky impurities that make the steel weak and brittle.

Who Was Henry Bessemer?

Before we dive deeper into the process, let’s talk about the guy behind it all – Henry Bessemer. This dude was a total innovator, always looking for ways to improve things. Born in 1813 in England, Bessemer spent his life tinkering with machines and inventing new ways to do things.

But here’s the cool part: Bessemer wasn’t just some random guy who stumbled onto this idea. He was a trained engineer with a knack for problem-solving. When he saw that the existing methods of making steel were slow and expensive, he knew there had to be a better way. And boy, did he deliver.

So, let’s take a closer look at the man behind the process:

Biography of Henry Bessemer

| Full Name | Henry Bessemer |

|---|---|

| Birth Date | January 19, 1813 |

| Death Date | March 15, 1898 |

| Place of Birth | Charford, Hertfordshire, England |

| Profession | Engineer, Inventor |

| Known For | Developing the Bessemer Steel Process |

As you can see, Bessemer was more than just a guy with a good idea. He was a true pioneer in the field of engineering, and his contributions to the steel industry are still felt today.

The Impact of the Bessemer Steel Process

So, what did this process actually do for the world? Well, let me tell you, it was a game-changer. Before the Bessemer Process, steel was expensive and hard to come by. This meant that most people couldn’t afford to use it for building or manufacturing. But once Bessemer came along, everything changed.

Here are just a few of the ways the Bessemer Steel Process revolutionized the world:

- Lower Costs: By making steel production faster and more efficient, the Bessemer Process drastically reduced the cost of steel. This meant that more people could afford to use it, leading to all kinds of new innovations.

- Improved Quality: The process also resulted in higher-quality steel, which was stronger and more durable than anything that had come before. This made it perfect for building things like bridges, railroads, and skyscrapers.

- Increased Production: With the Bessemer Process, steel could be produced on a much larger scale than ever before. This allowed for the rapid expansion of industries that relied on steel, from construction to transportation.

It’s kind of like how the invention of the assembly line made cars more affordable and accessible. The Bessemer Process did the same thing for steel, making it a staple of modern industry.

Challenges and Criticisms

Of course, no innovation is without its challenges. While the Bessemer Steel Process was a huge step forward, it wasn’t without its drawbacks. For one thing, it only worked with certain types of iron ore, which limited its use in some areas.

Additionally, the process could be pretty rough on the environment. All that air-blasting created a lot of smoke and pollution, which wasn’t exactly great for the surrounding communities. And let’s not forget about the workers – the conditions in Bessemer steel plants were often harsh and dangerous.

But despite these challenges, the Bessemer Process was still a major breakthrough. It paved the way for future innovations in steel production, many of which addressed these early issues.

Modern Applications

Nowadays, the Bessemer Process has largely been replaced by newer, more efficient methods of steel production. But that doesn’t mean it’s been forgotten. In fact, the principles behind the Bessemer Process are still used in many modern steel-making techniques.

For example, the basic idea of using air or oxygen to remove impurities from molten metal is still a key part of the Basic Oxygen Steelmaking (BOS) process, which is one of the most common methods of steel production today. So, even though the original Bessemer Process isn’t used much anymore, its legacy lives on in the industry.

Why is This Important Today?

Understanding the Bessemer Steel Process is important for anyone who wants to know how we got to where we are today. It’s a reminder of how innovation and ingenuity can change the world, even in the face of challenges and setbacks.

And let’s not forget about the environmental impact. As we continue to develop new technologies, it’s crucial that we learn from the mistakes of the past and strive to create solutions that are both effective and sustainable. The Bessemer Process may have had its flaws, but it also showed us what’s possible when we push the boundaries of what we know.

Comparing Bessemer Process with Other Steel-Making Methods

Now that we’ve covered the basics of the Bessemer Process, let’s take a look at how it stacks up against other methods of steel production. Here’s a quick rundown:

- Bessemer Process: Fast and cheap, but limited in its application and not great for the environment.

- Open Hearth Process: More flexible than Bessemer, allowing for the use of different types of iron ore. However, it’s slower and more expensive.

- Basic Oxygen Steelmaking (BOS): Combines the speed of Bessemer with the flexibility of Open Hearth, making it the go-to method for modern steel production.

- Electric Arc Furnace (EAF): Uses electricity to melt scrap metal, making it more environmentally friendly than other methods. However, it’s not suitable for all types of steel.

As you can see, each method has its own strengths and weaknesses. The Bessemer Process may not be the best option anymore, but it was definitely a crucial step in the evolution of steel production.

Future of Steel Production

Looking ahead, the future of steel production is all about sustainability. As we become more aware of the environmental impact of our industrial processes, there’s a growing push to develop methods that are both efficient and eco-friendly.

One promising development is the use of hydrogen instead of carbon in the steel-making process. This could drastically reduce the amount of CO2 emissions produced by steel plants, making them much more environmentally friendly.

Another exciting possibility is the use of advanced materials that can be produced with less energy and fewer resources. These materials could revolutionize industries ranging from construction to aerospace, just as the Bessemer Process did in its time.

Conclusion

So there you have it – the story of the Bessemer Steel Process and how it changed the world. From its humble beginnings as a simple idea to its role in shaping the modern world, the Bessemer Process is a testament to the power of innovation and human ingenuity.

But the story doesn’t end here. As we continue to push the boundaries of what’s possible in steel production, we have the opportunity to learn from the past and create a more sustainable future. Whether it’s through new technologies or improved methods, the legacy of the Bessemer Process will continue to inspire us for generations to come.

So, what do you think? Did you learn something new today? If you enjoyed this article, be sure to share it with your friends and check out some of our other content on the history of technology and industry. And who knows? Maybe one day, you’ll be the one revolutionizing the world with your own big idea.

Table of Contents

- What Exactly is the Bessemer Steel Process?

- How Does it Work?

- Who Was Henry Bessemer?

- Biography of Henry Bessemer

- The Impact of the Bessemer Steel Process

- Challenges and Criticisms

- Modern Applications

- Comparing Bessemer Process with Other Steel-Making Methods

- Future of Steel Production

- Conclusion

- Geheimnis Gelftet Vegane Schoko Mousse Mit Seidentofu So Einfach

- Verhaltensweisen Verstehen Ein Umfassender Leitfaden

PPT Bessemer Steel Process PowerPoint Presentation, free download

:max_bytes(150000):strip_icc()/Bessemer-process01-3000-3x2gty-58b4e7c75f9b586046963aff.jpg)

The Bessemer Steel Process

Exploring Bessemer steel process and the story behind it MRS STEEL